Research in the field of thermal spray coating to new levels

02 Jul 2018

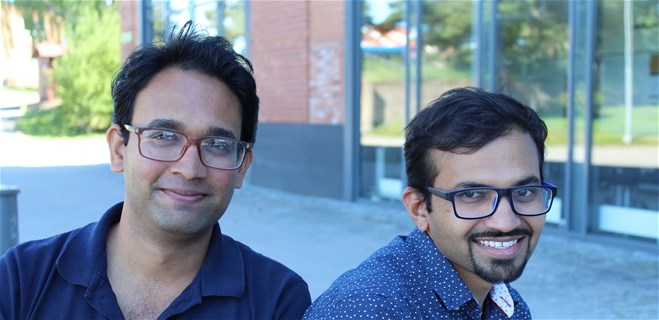

Lower fuel consumption, lower CO2-emissions and reduced costs for aerospace companies. These are the goals that Ashish Ganvir and Satyapal Mahade want to achieve with their research within thermal suspension coating. It is also about aviation safety. They both defended their doctor’s theses at University West in June.

Higher turbine inlet temperature in aero-engines makes for lower fuel consumption, lower CO2-emissions and lower costs. But when temperatures get too high, the properties of the aero-engine metals will change. Thus, heat exposed aero-engine components need to be protected.

A short step from India to Trollhättan

Plasma sprayed ceramic coating is a technology that has been used for more than 20 years. Within this field, University West holds a world leading position. Therefore, the step from India to the center of expertise in Trollhättan was not a big one for Ashish Ganvir and Satyapal Mahade. They both have a background in materials engineering.

Ashish visited University West for internship for the first time during a short summer period already in 2012.

– Then I came back for my master’s degree, he says. After that I was given the opportunity to proceed with my PhD research.

Satyapal took his master’s degree in India. During two years, he worked with patents for a business consultancy firm. To pursue his interest in research, he joined University West as a PhD researcher.

Want to see research results

The two newly-appointed PhD’s have several things in common. One is that they prefer to work with applied research.

– We’d like to live to see that the results of our research are used by the industry. We don’t have enough patience to do fundamental research, they state smiling.

Another thing that they have in common is that they have done their research in close cooperation with GKN Aerospace in Trollhättan. That connection comes natural since GKN is part of the aerospace industry.

Suspension instead of powder

Ashish Ganvir’s PhD thesis is titled ‘Design of Suspension Plasma Sprayed Thermal Barrier Coatings’. Behind the title is a new technology that meets aerospace industry needs; namely the technical requirements to use higher combustion temperatures in aero-engines to improve engine efficiency and, hence, minimize greenhouse gas emissions.

– In today’s technology, melted powder is sprayed on the gas turbine components, explains Ashish. It creates a thermal barrier layer of about half a millimeter. It also prevents oxidation and corrosion. The powder is an oxide of Yttrium and Zirconium called Yttria stabilized Zircona (YSZ).

– Instead of solid YSZ-powder I have been working with suspensions, i.e., finely grained powder mixed with ethanol/water.

Like spraying with paint

The suspension is sprayed under high pressure onto the components. Ashish Ganvir compares to spraying with paint. When the paint dries, the color pigment remains. Suspension spraying works the same way. When the solvent has evaporated, the components are covered by a hard and heat resistant layer.

– The suspension spraying technique is highly versatile. You can spray thin layers as well as thick ones. Dense layers as well as porous.

– The wide range of possibilities to create different layers can meet specific needs when used in other applications than thermal barriers. They offer superior properties in comparison to the coating that the industry uses today.

Progress for air safety

Conventional YSZ-coating cannot withstand combustion temperatures that exceed 1,200 °C. Furthermore, YSZ is sensitive to desert sand, volcanic ashes and fly ash from e.g., industries. When sand, ashes or soot pass into aero-engines, they melt and will eventually cause catastrophic failure to the engine.

Satyapal Mahade’s research aims at mitigating the risks that emerge at temperatures above 1,200 °C. His PhD thesis title is ‘Functional Performance of Gadolinium Zirconate/YSZ Multilayered Thermal Barrier Coatings’.

Just like his colleague, he uses suspension plasma spraying technology to apply the thermal barrier onto the exposed aero-engine components. But the powder features a new composition.

– I have done research on Gadolinium Zirconate GZ, which is a compound of gadolinium oxide and zirconiumoxide, explains Satyapal.

– We use suspension plasma spraying to put a separate GZ-layer over the YSZ-coating. That makes it feasible to raise aero-engine combustion temperatures above 1,200 °C.

– Furthermore, the thermal GZ-coating has properties that withstand desert sand, volcanic ashes and soot without allowing for engine damages. From an air safety point of view, this is a very important step for air traffic in many countries.

See other possible applications

Both Ashish’s and Satyapal’s research has been met with large international interest.

As extensions of their current work, they see other possible applications. The suspension spraying technology can be used in land-based power plants, in certain components in space rockets and in diesel engines for the auto industry.

A completely different field of application is biomedical engineering. You can e.g., coat surfaces on implants to enhance performance when you replace peoples’ hip- or knee-joints.

Yet another field where suspension spraying can become useful is on surfaces that shouldn’t be covered with ice. It is now possible to design coatings where water cannot attach and, consequently, not freeze. The same principle can be used for designing antibacterial coatings, which may prove extremely valuable for e.g., fresh water reservoirs.

– The suspension spraying technology is cheap and we see lots of possibilities to use it, state Ashish and Satyapal.

Text and photo: Ulf Axelson