Production flow simulations

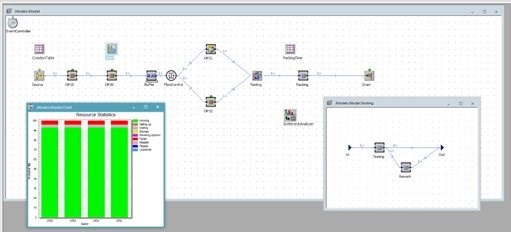

This research focused on challenges and opportunities for initiation, or extended applications, of production flow simulation i.e., discrete event simulation (DES) as a tool for decision support in the era of industry 4.0.

Throughout the project the applicability of DES was studied in co-production with the partner company and research delved into the areas of real time data, statistical process control (SPC), artificial intelligence (AI) i.e., neural networks and reinforcement learning and digital twins. The initial results concluded complexity of introducing DES as a new tool for decision making emphasizing human knowledge and involvement is yet necessary to understand and to draw conclusions from the data.

Specific concepts investigated:

- Utilizing RFID-stickers on the products was proposed for reaching real time data model updates.

- Coupling the DES with Statistical Process Control.

- Incorporating an AI tool using neural networks into the DES solution.

Both approaches, SPC and AI tool, are aiming towards solving the same task of automatically analyze the performance of the production using DES as a source of generating data/information needed

Qualitative data was gathered in parallel with technical development, resulting in 18 qualitative interviews with management, shop floor personnel, team leaders and support functions, such as logistics managers and functions responsible for digitalization development. The results from investigating the human-centric aspects highlight the challenges of implementing and especially trusting digital tools. To realize the value of digital tools for production planning and control, it is argued that it is imperative to simultaneously apply a human-centric perspective in decision making to ensure trustworthy, sustainable, and resilient human-data-technology nexus implementations towards smart manufacturing.