The world's top experts in thermal spraying meet at University West this fall

17 May 2023

For the first time ever, one of the world's leading conferences on thermal spraying with liquid feedstock is being held outside North America. University West will be the host when researchers and global industry players meet at the Thermal Spray of Suspensions & Solutions Symposium & EBCs (TS4E) in September 12-13, 2023.

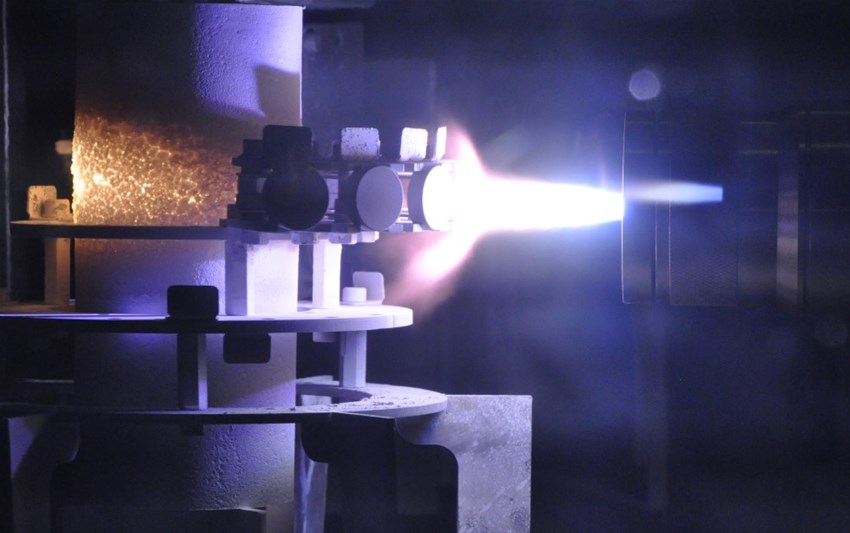

Thermal spraying is used to add new surface layers to components so that they get better properties or new functions. Photo: Stefan Björklund, University West.

The conference is organized by the world’s largest materials information society, ASM International. Over a hundred researchers, product developers and other experts in thermal spraying from different parts of the world will meet in Trollhättan, Sweden, to exchange knowledge and experience. Among the presenters are well-known industry players such as NASA, General Electric, Safran, Höganäs AB, MetTech, Oerlikon Metco, Treibacher Industrie AG, Lincotek Surface Solutions and Mitsubishi Heavy Industries (MHI).

“We are extremely proud to host this conference. Although University West is one of Sweden's youngest universities, we conduct cutting-edge research in thermal spraying, especially in suspension spraying and suspension solutions, which is the theme of this conference”, says Shrikant Joshi, Professor of Thermal Spraying.

“Hopefully we can attract more European universities and companies to participate now that the conference is organized in Europe. We also aim to attract students, doctoral students and postdocs to the summer school in thermal spraying that we are organizing the day before the TS4E conference.”

Gives components better properties

Thermal spraying is used to add new surface layers to components so that they get better properties or new functions. The technology is used in new production, repair and maintenance.

Interest in thermal spraying is increasing strongly within a number of different industries. The aerospace and automotive industries see the technology as a solution to reduce the emissions of climate-damaging substances in jet engines and diesel engines. At University West, several research projects are underway in close collaboration with industrial partners such as GKN Aerospace, Siemens Energy, Scania, Volvo and others.

“Our research in thermal spraying spans a range of different applications. Technology can be used to improve products and increase their lifespan in many different ways. It can be about everything from developing more efficient gas turbines in electric power plants, to purifying polluted water in water tanks.”

Global leader

University West’s research in thermal spraying started soon after the institution was founded in 1990. Three decades later, the university's research in the field has a globally leading position.

“We have a scientifically strong research environment with access to advanced equipment for plasma spraying and high-speed flame spraying (HVAF). With financial support from the KK Foundation and other financiers, we have fantastic opportunities to develop research in close collaboration with industrial partners and other research groups worldwide.”

-------------

This is how thermal spraying works

Thermal spraying can be simply described as spray painting a component. You use a heated material in powder form that is pushed at high speed onto the surface you want to coat. When it lands on the surface, the powder particles are deformed and spread like a thin pancake which then solidifies. You can spray several layers of "pancakes" and then build up a new, stronger surface step by step.

Common materials are metal, metal alloys, composites, ceramics and polymers. The powdered material can also be mixed with a liquid and used for so-called suspension spraying.

Contact: Shrikant Joshi, Professor of Thermal Spraying, West University