“Amir’s research is valuable for our product development”

Amir Parsian’s research became an important contribution to Sandvik Coromant’s development of a new generation of indexable insert drills. “It is extremely valuable incorporate the scientific research methodology into product development. It provides a basic understanding of the technology, which contributes to increasing the quality of new products,” says Martin Magnevall, who served as Amir’s supervisor.

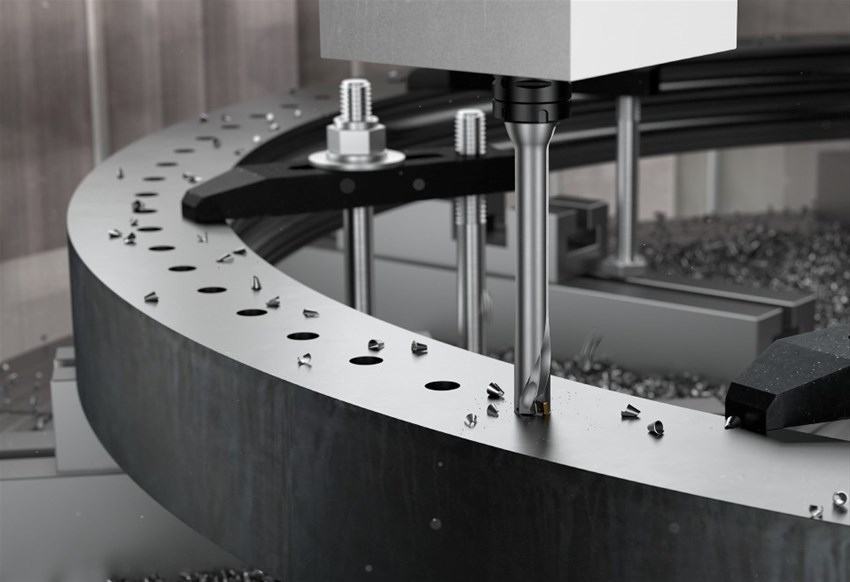

Amir Parsian's research became an important contribution to Sandvik Coromant's development of a new generation of indexable insert drills. Photo: Sandvik Coromant

Over the past ten years, several externally employed doctoral students have contributed to Sandvik Coromant’s product development at the head office in Sandviken. Amir Parsian is one of two doctoral students affiliated with the SiCoMaP industrial research school at University West.

“Having externally employed doctoral students involved in regular product development creates valuable synergies while allowing product developers to follow relevant ongoing research and acquire new knowledge and skills. The company has been developing tools for almost 80 years but still has a continual need for improvement,” says Martin, who now works as a senior lecturer at Blekinge Institute of Technology.

“Amir was hired to participate in the development of a new generation of indexable insert drills, which turned out to be a very successful project. Among other things, he has contributed valuable knowledge through his work in modelling and analysing measurement data,” says Martin.

Amir first did his master’s dissertation at Sandvik Coromant as part of his earlier studies at Blekinge Institute of Technology.

“I like to explore issues of relevance for industry, so when Sandvik advertised for an externally employed doctoral student, it was a natural step for me,” says Amir.

“It is extraordinary to be able to learn the scientific method used in research, while at the same time having the opportunity to apply new knowledge to concrete projects where experiments and tests are conducted in close connection to products and the market,” says Amir.

“One advantage is the rapid feedback from customers on what works and what does not. I have also gained insight into the economic aspects of product development.”

Amir is pleased to have been involved in the development of a new, more advanced drilling tool. Today, he works on new projects in the company’s R&D department.

“I benefit greatly from the knowledge gained through my doctoral studies. My work primarily involves analysing measurement data to better understand what happens in manufacturing processes. As industry digitalises, the need for this type of knowledge is growing. The more digitalised production processes become, the greater need for data analysis.”