CLOUDS - Intelligent algorithms to support Circular soLutions fOr sUstainable proDuction System

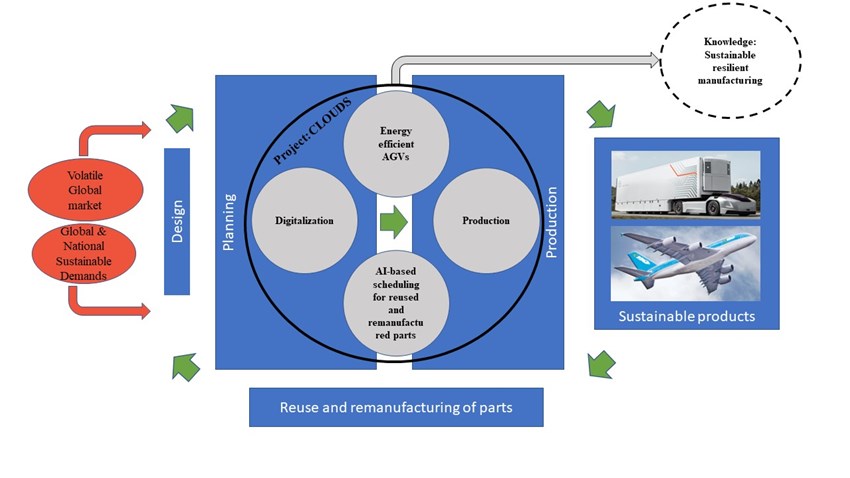

CLOUDS develop an AI based sustainable production system which is capable of handling the process planning, virtual commissioning, optimizing the production schedule, addressing the bottleneck issues in mixed model assembly and balancing the production line with human workload.

The project Intelligent algorithms to support Circular soLutions fOr sUstainable proDuction Systems (CLOUDS) focus on AI-based tools for flexible production systems enabling sustainable manufacturing of electrified vehicles and remanufacturing of products. Expected results hope to endorse industries to become more resource-efficient, sustainable, and address circularity. The project constellation consists of University West (project management), Chalmers, GKN, and AB Volvo. The three-year project is financed by Vinnova under the call "Increased resource efficiency for a sustainable industry 2022” and received financing of 2 900 000 SEK.

Purpose and goal

CLOUDS will deliver AI-based tools for flexible production systems enabling sustainable manufacturing of electrified vehicles and remanufacturing of products.

Goal 1: An online AI-based robust scheduling tool for optimizing the production flow, including the aspect of human workload, and eliminating bottlenecks.

Goal 2: An efficient and sustainable method to continuously keep digital models of the production up to date to be used for optimization and frequent virtual commissioning.

Goal 3: An optimization algorithm for resource- and energy-efficient AGV material handling.

Expected effects and results

CLOUDS results promote industries to become resource-efficient, sustainable, and address circularity.

(1) An AI-based tool that tunes line balance, adjusts production demand, and balances human workload in the production line.

(2) For resource efficiency, a sustainable automated smart digitalized tool will be developed.

(3) Robust and resilient scheduling tool for efficient resource management and optimal energy use of AGVs.

(4) Demonstrate the digital model functionality, optimization strategy, and virtual commissioning method in an industrial testbed.

Planned structure and implementation

Partner companies will provide data to develop the tools, leading to research results that improve the virtual preparation and commissioning processes, as well as minimizing the environmental footprint of new production systems. The other academic partner will be involved in developing the algorithms and conducting experiments. A state of the art industrial testbed is available at the Production Technology Center (PTC) at UW in Trollhättan, where different scenarios of real industry setups can be created and the results can be validated before bringing them to the industry.

Research Area

- Teknik

- Produktionsteknik

Research environment / Institution

- Produktionsteknik

- Primus (KK-miljö)

- Institutionen för ingenjörsvetenskap

Project leader

Participants University West

Research Partner

- Chalmers tekniska högskola

- GKN Aerospace

- AB Volvo

Research funding

- Vinnova

Project time

2022 - 2025